Service

Service

Stamperia SB specialises in the hot forging of brass parts. Founded in 1967, it has two large production facilities located in Paderno Franciacorta (Brescia) and Invorio (Novara), both in northern Italy. We manufacture to order based on designs and specifications.

The production cycle

Feasibility study

A targeted estimate is prepared based on the study of the requested part.

Press designing and manufacturing

Our technical office analyses and develops customer designs and projects. We then manufacture a mould and potential supporting equipment.

Analysis turnaround time and methods

In this phase we analyse the turnaround and methods to optimise the production cycle.

Raw material

The Logistics Office deals with the management of brass bars, preparing them for forging in compliance with current regulations.

A targeted estimate is prepared based on the study of the requested part.

Press designing and manufacturing

Our technical office analyses and develops customer designs and projects. We then manufacture a mould and potential supporting equipment.

Analysis turnaround time and methods

In this phase we analyse the turnaround and methods to optimise the production cycle.

Raw material

The Logistics Office deals with the management of brass bars, preparing them for forging in compliance with current regulations.

Material used

Hatebur forging

- CW617N

- CW510L

- CW602N

- CW617N

- CW510L

- CW602N

- CW625N

- CW511L

- CW612N

- CW626N

- CW725R

Hot forging

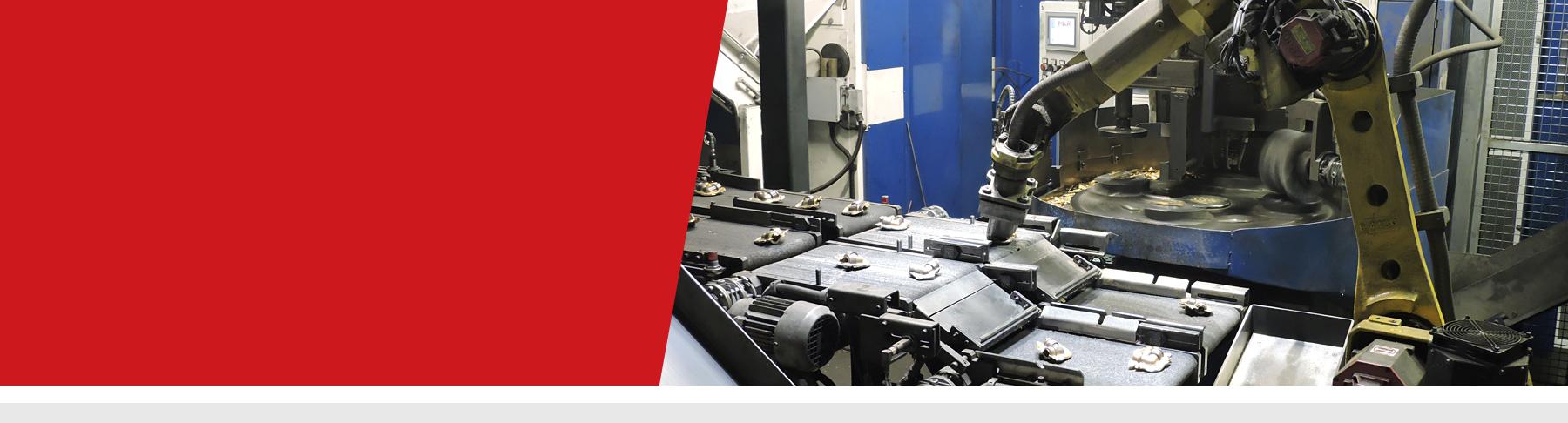

As needed, forging is performed with horizontal Hatebur presses for nuts, spheres and sleeves, or with vertical presses for fittings and valves.

Blanking

Performed using modern robotic islands or shears.

Superficial treatments

All treatments are performed on request. We perform sand-blasting to clean forged parts and to improve the surface appearance.

Quality control

Throughout the entire production cycle, Quality Control ensures that items meet the geometric characteristics and properties ordered during the planning phase.

Logistics

The orderly management of the warehouse and the resulting punctuality of shipments are essentials for our company.